The first “real world” project on the Pocket NC was to create 2 replacement Oilite bushes for the mains powered Synchron motor in a 1940’s Kit Cat Clock.

The first “real world” project on the Pocket NC was to create 2 replacement Oilite bushes for the mains powered Synchron motor in a 1940’s Kit Cat Clock.

Following on from a previously outlined move to Deno I’ve now moved to Bun 😅

The main thing I moved to Deno for was a nice way to acheive:

After a while I discovered these items don’t all work well together. It came to light that dynamic loading of modules external to the compiled Deno application was not really supported: https://github.com/denoland/deno/issues/18327 Fair enough, everyone has their priorities…

I then read (but can’t remember where) that Bun does support this. 🥳 Ok, game on!

I took some time during the holiday to get the Minitel I inherited from the parents-in-law connected to my home server. As I already run Asterisk on the server and have analogue telephony hardware, I wanted to use the analogue dialup modem rather than opting for the serial port available on some Minitel terminals.

Overall the setup is:

Analogue Phone + Minitel Terminal => Grandstream ATA => Asterisk => SoftModem => Python Minitel Server

Here is a video showing initial connection and navigating to some adult content of the era:

A second attempt at the tutorial from Penta was reasonably successful.

The first attempt was most definitely not: the collet I used didn’t tighten up on the workpiece enough and the workpiece moved towards the mill during the operation. As I looked on in awe at the increasing size of the chips without thinking to intervene, the mill eventually plunged into the workpiece which then moved and snapped the mill. I have video but won’t publish that… As I said: not successful, beginner chips 🥹

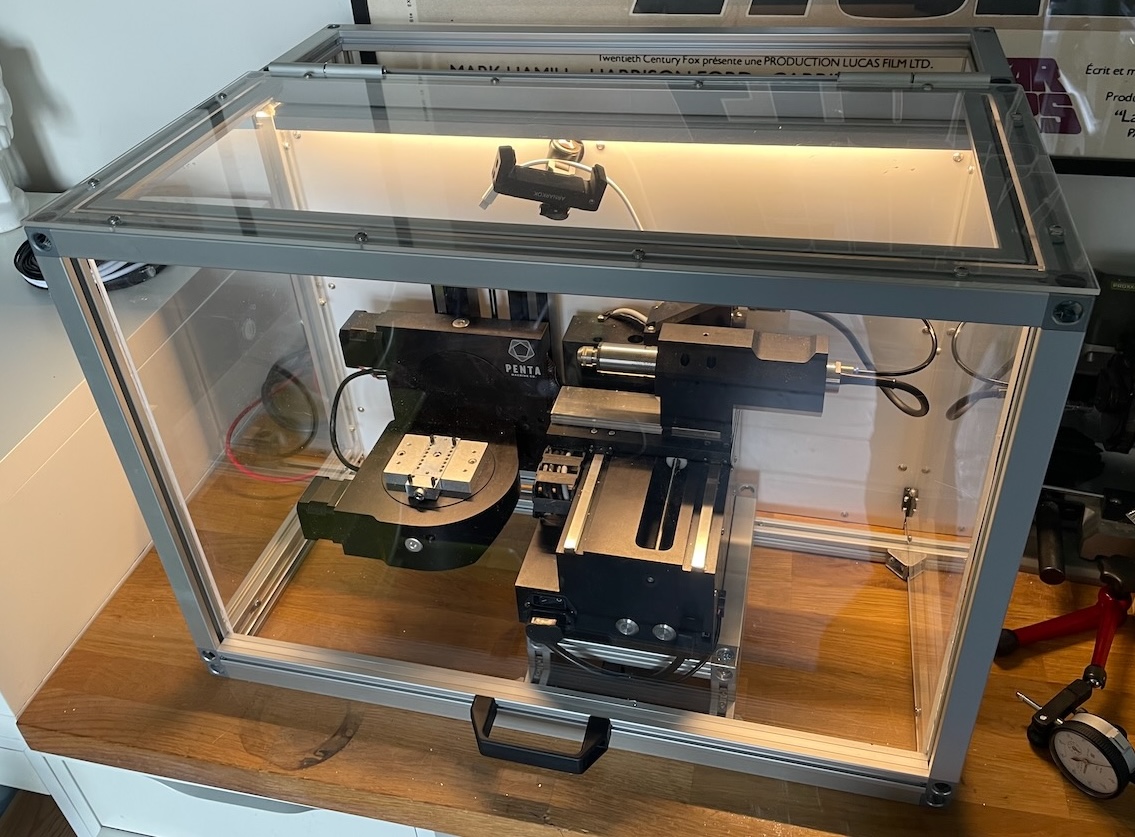

Over a long duration I finally constructed the Pocket NC enclosure. And now after an even longer period of time I am posting about it.

Features include:

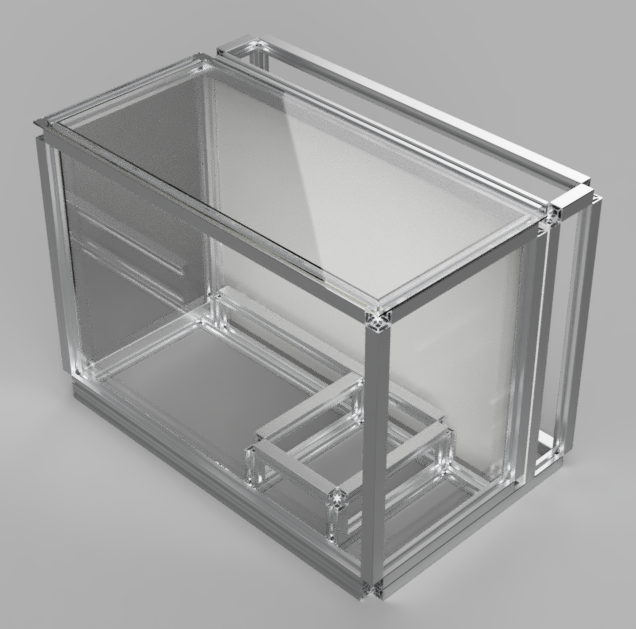

Before getting serious with the Pocket NC V2-50CHK, I want to build an enclosure for it. Although there is one available to buy commercially, I wanted to build a custom one myself that has:

The first chips have been produced on my new pride and joy, the Penta Machine’s Pocket NC V2-50CHK!

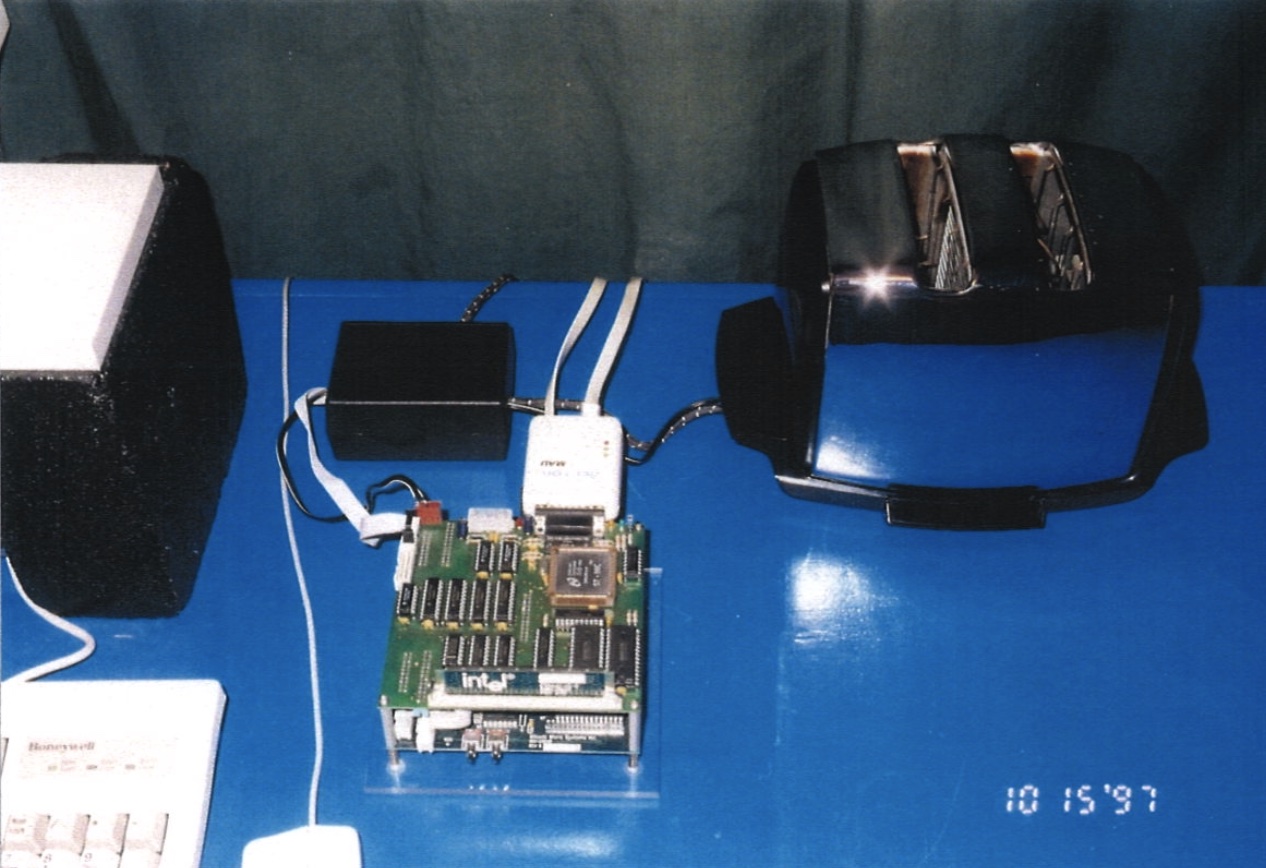

I’ve held onto the hard copy of my Electrical Engineering Thesis for around 25 years. It recently suffered water damage so I decided it was time to immortalise it on the world wide web.

I say ‘world wide web’ in preference to modern terminology such as ’net’, ‘web’ etc. in homage to the title of the thesis:

A TOASTER WITH A WORLD WIDE WEB INTERFACE.

Here is a photo of the ‘completed’ project:

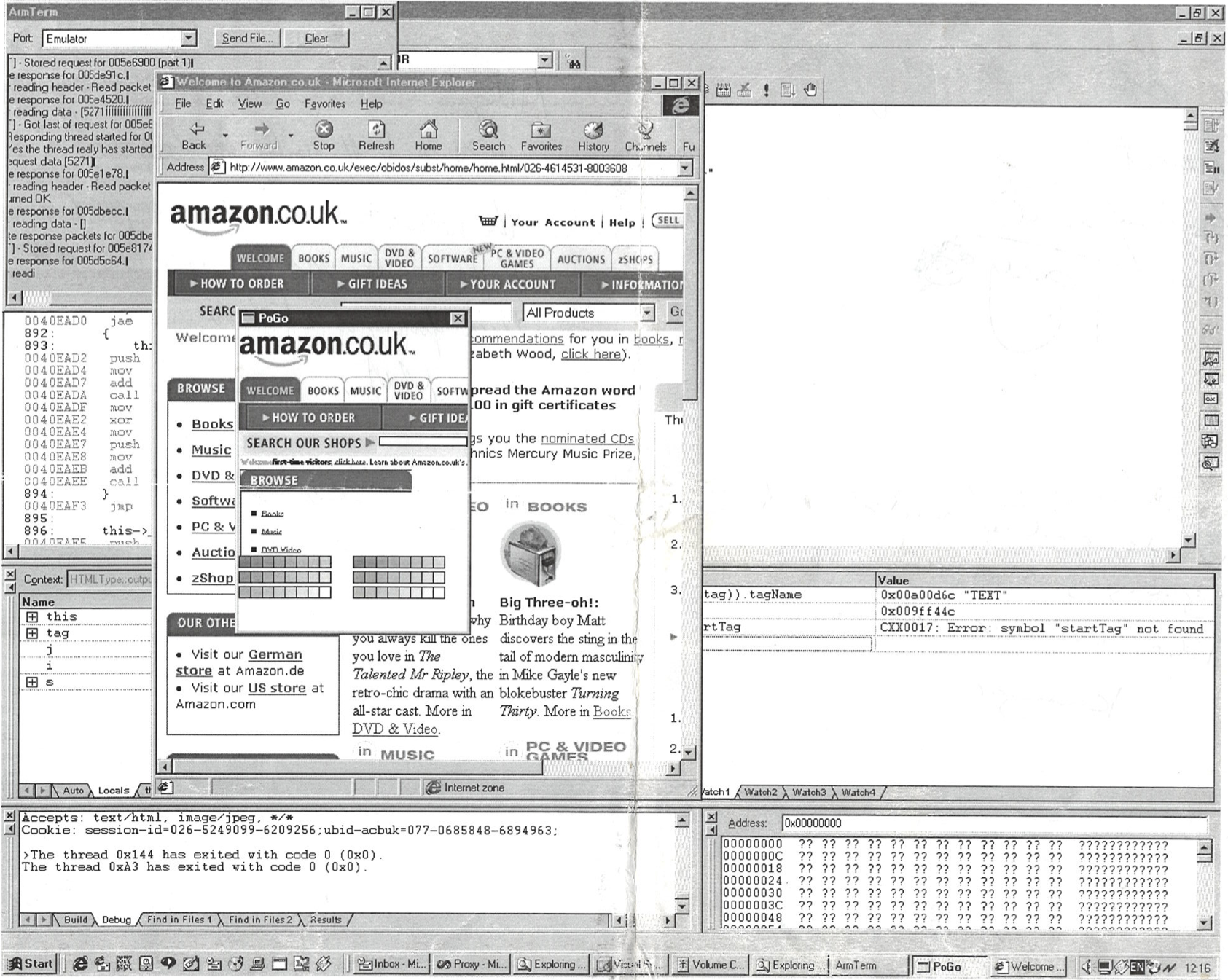

More than 20 years ago, in the ‘dotcom’ era, I worked for the web design agency Razorfish and managed to get involved in a more exciting gig working for a hardware spin-off developing the Pogo Mobile.

I was responsible for the development of the embedded web browser that acted as the sole UI for the device.

I came across this printout of a screenshot I took when the browser rendering started to take shape.

Life is all about incremental steps forward. And… some steps backwards and sideways as well…

I switched from FreeCAD to Fusion 360 as I want to end up doing some 5 Axis CNC Machining. Currently FreeCAD support for this is very… far… away…

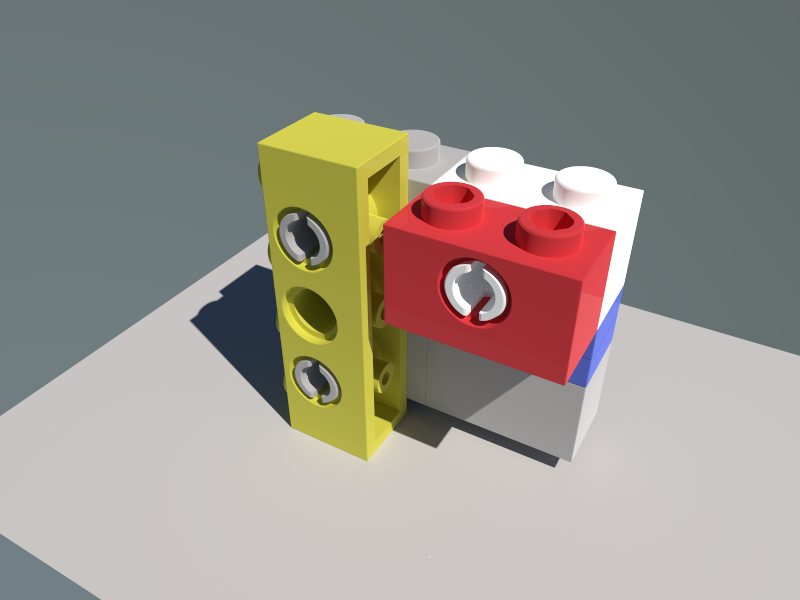

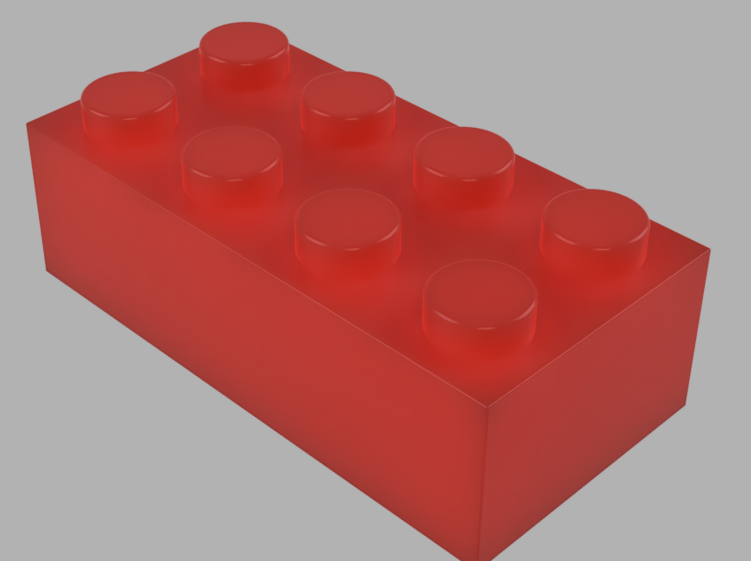

So here are the results of applying the same learning process of modelling a brick in Fusion 360:

And here is the online model: https://a360.co/3dLLBre

Presenting a set of template Rust, WASM and Deno projects on GitHub which make use of GitHub Actions and Workflows for continuous integration.

I’ve previously outlined my reasons for evaluating Rust and Deno. Using these technologies, I am looking to achieve:

I wanted to see if these could all be achieved using free SaaS tooling for continuous integration including:

I created the template projects and GitHub workflow and actions discussed here to see if the technologies could deliver on their promises and thus achieve my aims.

A new feature release version of Legify is available at:

https://github.com/vectronic/freecad-legify-macros/releases/tag/v0.4.0

This provides a new legify-technic-pin macro which renders a technic pin onto an existing Part Design workbench body.

Therefore the “s” in the name of the project “freecad-legify-macros” now has real meaning! 😜

I ordered some 3D prints of bricks designed with the legify macro code available at:

https://github.com/vectronic/freecad-legify-macros

Presented below are two assemblies as rendered within FreeCAD and assembled in real life.

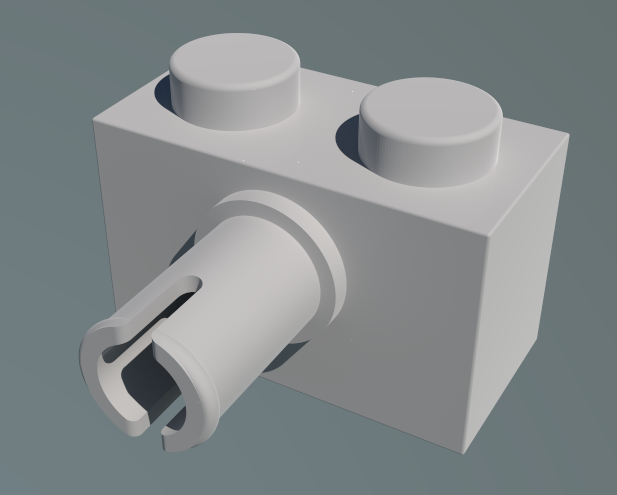

A new feature release version of Legify is available at:

https://github.com/vectronic/freecad-legify-macros/releases/tag/v0.3.0

Beyond a number of measurement improvements, rendering of technic pins is now implemented.

I have just completed the finishing touches on Technic pin support: