The first “real world” project on the Pocket NC was to create 2 replacement Oilite bushes for the mains powered Synchron motor in a 1940’s Kit Cat Clock.

The first “real world” project on the Pocket NC was to create 2 replacement Oilite bushes for the mains powered Synchron motor in a 1940’s Kit Cat Clock.

A second attempt at the tutorial from Penta was reasonably successful.

The first attempt was most definitely not: the collet I used didn’t tighten up on the workpiece enough and the workpiece moved towards the mill during the operation. As I looked on in awe at the increasing size of the chips without thinking to intervene, the mill eventually plunged into the workpiece which then moved and snapped the mill. I have video but won’t publish that… As I said: not successful, beginner chips 🥹

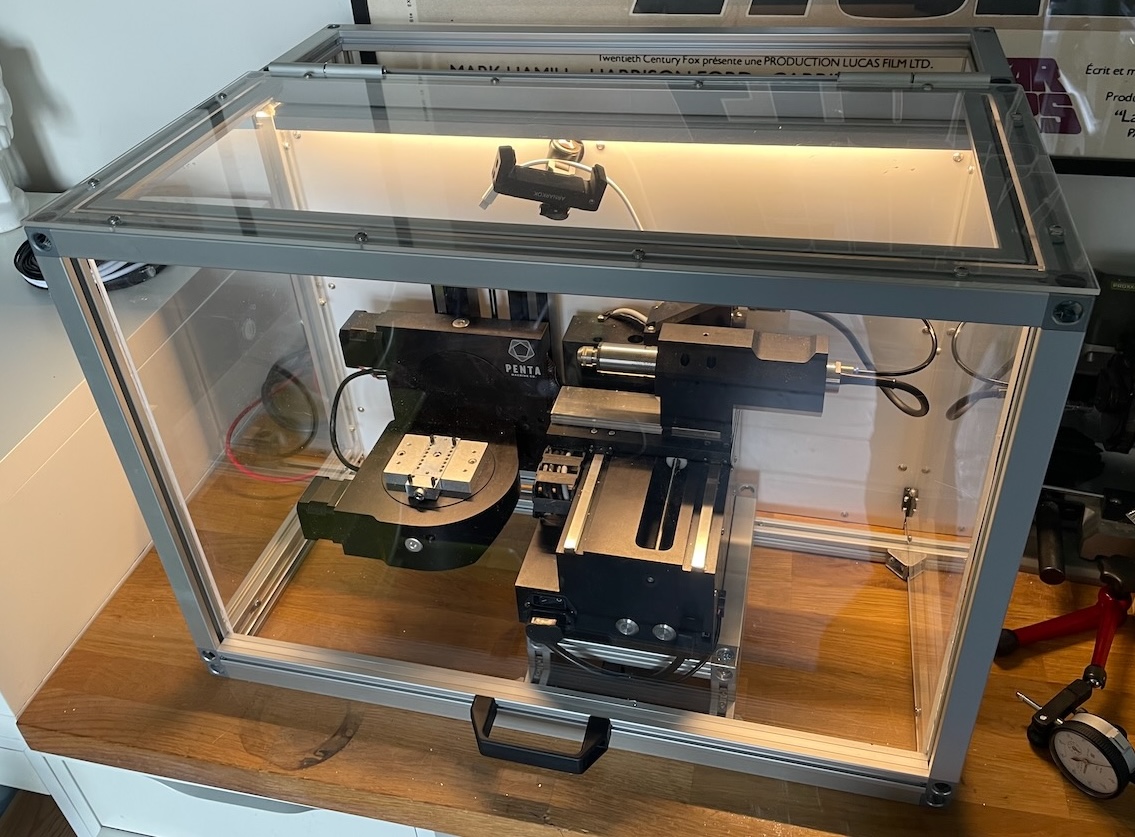

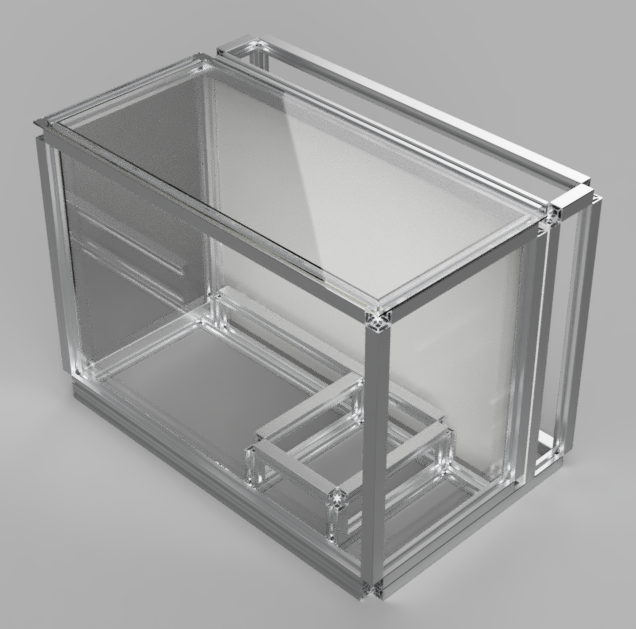

Over a long duration I finally constructed the Pocket NC enclosure. And now after an even longer period of time I am posting about it.

Features include:

Before getting serious with the Pocket NC V2-50CHK, I want to build an enclosure for it. Although there is one available to buy commercially, I wanted to build a custom one myself that has:

The first chips have been produced on my new pride and joy, the Penta Machine’s Pocket NC V2-50CHK!